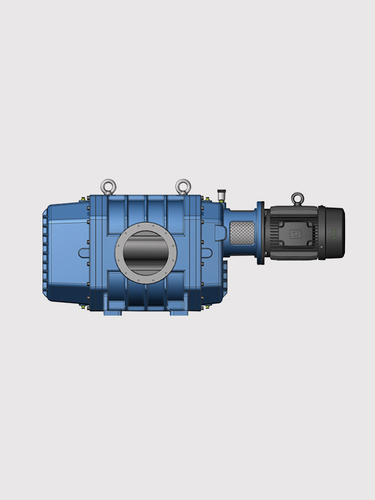

The following is a description of the products of our company (DVE Sanmen Development Vacuum Equipment Co., Ltd.).

Classification

The distinction method is mainly distinguished by the number of rotor blades

The name of the ordinary Roots vacuum pump generally refers to the two-leaf Roots vacuum pump, and its rotors are two "8" in the pump.

At present, there are also three-lobe Roots vacuum pumps that are produced more, and the rotor in the pump body is a three-lobe type.

Note: If you do not understand the above two differences, you can view the corresponding rotor diagram.

The difference between ZJP and ZJ on the model is that the internal mechanism of the air outlet is the same. ZJP type has down pass and side pass with overpressure protection valve, ZJ type only has down pass.

Features

1: There are gaps between the rotor and the pump body, the side cover, the rotor and the rotor, and they do not contact each other. Therefore: A. There is no friction between the moving parts of the pump chamber, so the power consumption is small, the operation and maintenance costs are low, and the energy saving effect is Significantly. B. The moving parts in the pump chamber do not need oil lubrication and sealing with each other, which avoids the contamination of the vacuum system caused by the backflow of oil vapor. C. Roots vacuum pump is not sensitive to a small amount of dust contained in the pumped gas.

2: The rotor has good geometric symmetry, stable operation, low vibration, low noise, high speed of direct drive, small size and light weight.

3: There is no internal compression in the pump chamber of the Roots vacuum pump like other mechanical vacuum pumps, so it does not need an exhaust valve, so when its backing pump adopts a water ring vacuum pump, it can pump out a large amount of water vapor. gas.

4: Quick start, can reach the ultimate vacuum in a short time, high pumping efficiency

5: The pump has a high pumping efficiency in a wide pressure range (1.3X10³~1.3Pa), and can quickly discharge the suddenly released gas, which makes up for the diffusion pump and oil-sealed mechanical pump when the pump is 1.3X10³~1.3Pa Defects of low pumping efficiency.

6. Reliable and durable work: each friction pair in the pump chamber is well lubricated, the bearing is separated from the pump chamber, and the pump shaft is equipped with a shaft sleeve at the shaft seal, so the main shaft will not be worn, and the shaft sleeve can be turned back to continue after wear. use. The vertical structure is adopted, the belt tension is offset by the gravity of the pump pulley, the bearing load is small, and the service life is long. The main parts are reasonably designed, the large fuel tank structure is conducive to the separation and cooling of oil and gas, and has a large oil storage capacity, which has a better self-separation effect on the sundries contained in the oil. According to the working conditions, it can also be equipped with a filter screen. The filter is automatically connected to the blocked bypass, and the oil flow display device in the oil circuit, so the pump can work for a long time and have a long service life, and can work in harsh working conditions.

7. Small size and light weight: the design speed is moderate, the structure is compact and reasonable, the utilization rate of the inside and outside of the pump cavity is the highest, the appearance is simple and the volume is small

Scope of application

It is widely used in the matching of single crystal furnace and ingot furnace, as well as vacuum coating, vacuum drying, vacuum degassing, vacuum impregnation, vacuum brazing in coating, electrical, smelting, chemical, ceramic, aviation, laboratory and other occasions. Welding, vacuum heat treatment, vacuum concentration, vacuum reaction, high-altitude simulation test, etc., it can not be used alone, it can be used with slide valve vacuum pump, screw vacuum pump, rotary vane vacuum pump, water ring vacuum pump and other fore-stage pumps to form a vacuum unit to achieve better results. higher vacuum, higher pumping efficiency.

Due to the characteristics of the Roots vacuum pump, different backing pumps can be freely selected according to different operating conditions, especially when the vacuum degree is not high, and it is required to remove weak corrosive gases containing a large amount of water vapor or a small amount of dust It can be used with water ring vacuum pump or reciprocating vacuum pump. Of course, matching with different forms of backing pumps, the ultimate pressure that the Roots vacuum pump can reach is also different, and the power consumed by the Roots vacuum pump working under different pressure differences is also different. DVE Sanmen expands the vacuum equipment Co., Ltd. can specially design Roots vacuum units of various types and specifications according to the user's vacuum process requirements and operating conditions.

Model meaning

Example: ZJ-220DV

ZJ: Roots vacuum pump (Roots booster pump)

220: Pumping rate 220 liters/sec

DV: stands for Expanded Vacuum Equipment (DVE)

The working principle of Roots vacuum pump

When the Roots vacuum pump is working, a pair of rotors in the pump chamber rotate synchronously in the direction of the arrow shown in the figure. The air inlet of the pump is sucked in (as shown in Figures A and B); with the further rotation of the rotor, the inhaled gas is closed into the closed V0 space (shown in the shaded part in Figure C), and then with the rotor Rotation, the gas in the V0 space is transferred to the exhaust chamber. Since the pressure in the V0 space is lower than the exhaust chamber at this time, the gas diffuses back from the exhaust port to the V0, but when the rotor rotates further, the exhaust gas is discharged. The air cavity is constantly shrinking, so more gas in the air cavity than the reflux is discharged from the exhaust port, thus forming the continuous suction and exhaust of the Roots vacuum pump

The mechanical working principle of the three-blade Roots vacuum pump is basically the same as that of the two-blade, the difference is that the three-blade Roots vacuum pump divides the rotor into three blades

Molecular action principle of Roots vacuum pump

Roots vacuum pumps work with very low inlet pressure. Due to the high speed of the rotor (the motors equipped with different models are different but all high), the linear speed of the rotor surface is close to the thermal motion speed of the molecules. At this time, the gas molecules colliding on the rotor are carried by the rotor to a higher pressure. The high exhaust side is then removed by the fore-stage pre-vacuum pump.

Under the combined action of the two principles, the Roots vacuum pump has the characteristics of high pumping speed and stable pumping speed curve in the range of (1.3X10³~1.3Pa).

Roots vacuum pump performance specification

Specification of main technical parameters

Specification of main technical parameters: model, pumping rate, limit partial pressure, limit total pressure, noise, pump speed, motor power, intake diameter, exhaust diameter, regular backing pump, cooling method, lubricating oil, weight ,

English

English Pусский

Pусский Chinese

Chinese