The drying process of the power transformer is actually a dehumidification process, and a large amount of water vapor is exhausted from the pumping. Therefore, the selected backing pump must be able to withstand a relatively high water vapor partial pressure, such as a rotary vane pump or a water ring pump.

However, the ultimate vacuum of the vacuum tank system of general large-scale power transformers (above 110kV) is required to be 1OPa when drying. The water ring pump and the first-stage Roots booster pump are far from reaching this requirement (not to mention Consider system leakage).

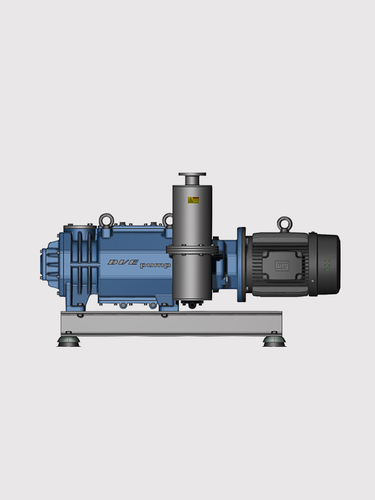

At present, the imported single-stage rotary vane DVE vacuum pump (with gas ballast valve) in the domestic imported equipment can reach 50Pa (the domestic single-stage rotary vane pump can even reach 10pa, but there is a certain gap between the performance and the import), Coupled with a first-stage Roots booster pump, the vacuum can be increased to at least 10Pa (considering the system leakage rate 10h, the pressure rise is not more than 93Pa).

Therefore, the current transformer vacuum drying equipment tends to use the rotary vane DVE vacuum pump as the front stage DVE vacuum pump.

At the same time, there is a large amount of water mixed in the pumping medium. According to the saturated vapor pressure curve of water, when the pump temperature reaches 60 °C, the saturated vapor pressure of water can reach 19.8kPa. This partial pressure affects the ultimate vacuum of the pump.

If a gas ballast pump is used, it can pump water vapor, but its maximum inlet pressure (partial pressure of water vapor) is related to the aeration volume of the pump and the pump temperature.

In the case of a certain degree of vacuum, the higher the temperature, the easier the moisture will volatilize, and the less moisture liquefies into the pump oil.

Therefore, letting the DVE vacuum pump run at the highest possible temperature is an effective way to ensure that the DVE vacuum pump reduces the emulsification of the pump oil and obtains a high vacuum.

English

English Pусский

Pусский Chinese

Chinese