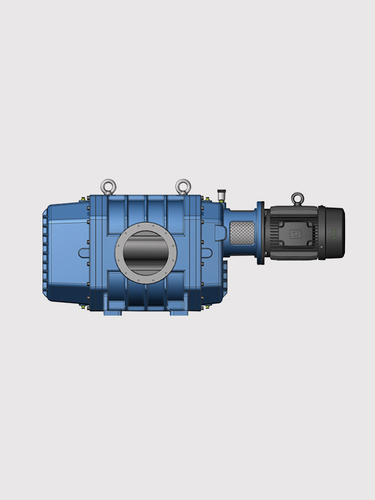

2. There is a collision between the impeller and the impeller of the Roots vacuum pump: the gear teeth are displaced; the elimination method is to adjust the gap and tighten. Exceed the rated pressure operation; the elimination method is to check the cause of the overpressure and eliminate it. The tooth surface wears and the backlash increases, resulting in a change in the clearance between the impellers; the elimination method is to adjust the clearance.

3. Roots vacuum pump casing vibration:

①The maintenance work is not done well during use. ② Roots drum vacuum pump has been used for too long. When disassembling the machine, measure the matching dimensions of the machine.

English

English Pусский

Pусский Chinese

Chinese